SIMPLE

The Roofway standind seam roof offer full guarantee for tightness, fast execution, and a very attractive architectural result.

Possible solutions in roofing and facades project with an excellent cost-benefit and minimum inclinations.

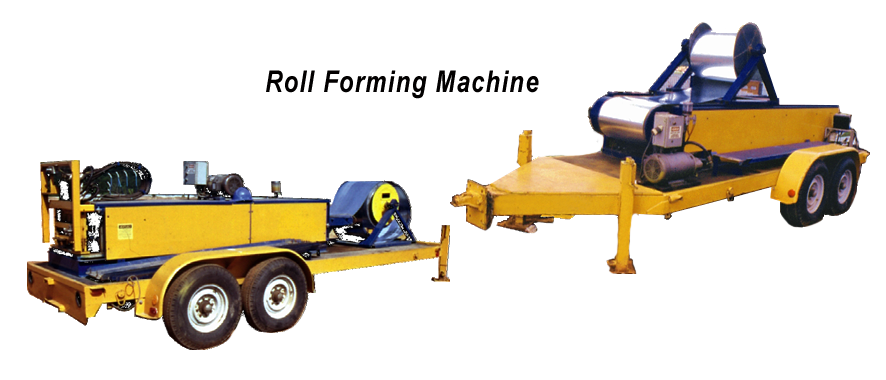

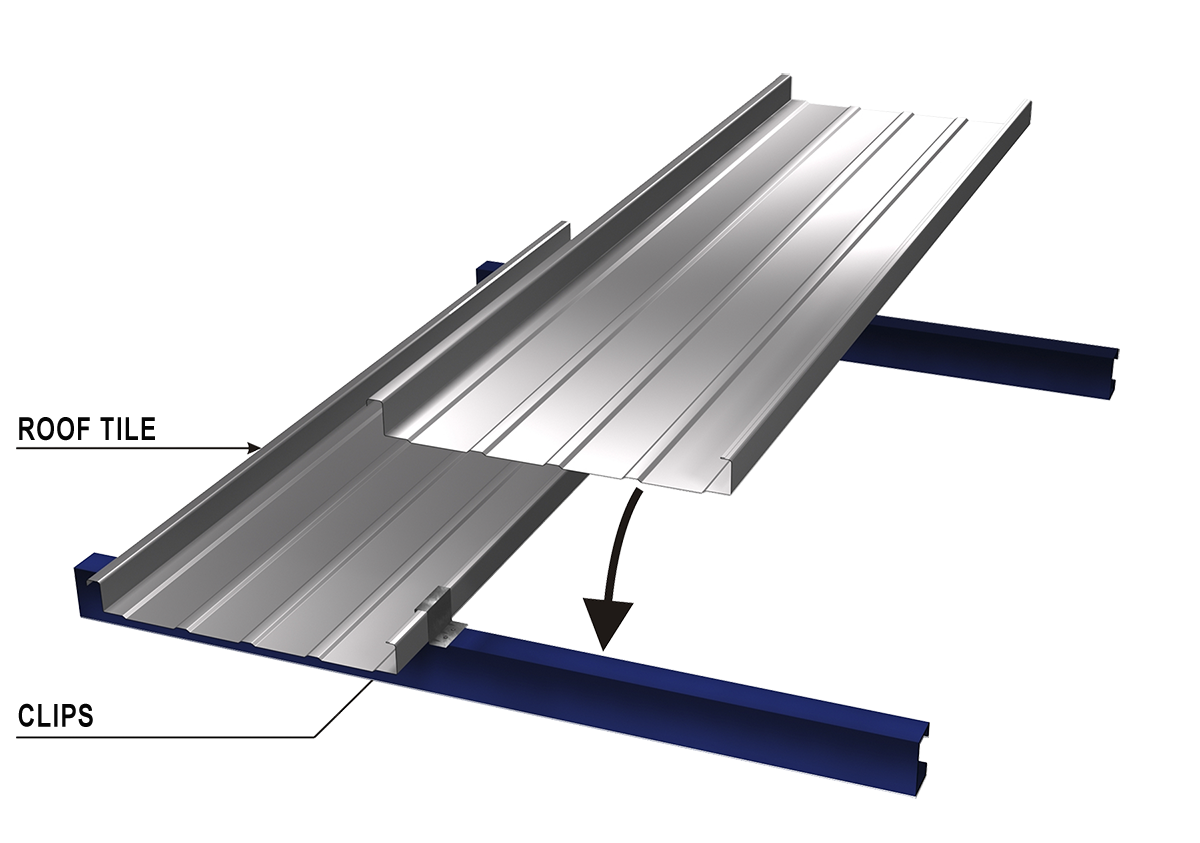

The sheets are profiled on construction site, continuously, with no length limits and without seam, and are fixed through the process called standing seam roof, using special clips without drilling on the sheets.

Doing what he knows best, boldly and careful planning, the Roofway by Kalzip is continually investing in technology for the pursuit of excellence.

Basically, the system consists of the manufacture of sheets on construction site, continuously, without limits in length, seamless, without drilling on the sheets and consequently '’Total tightness guarantee! "

Available Profiles

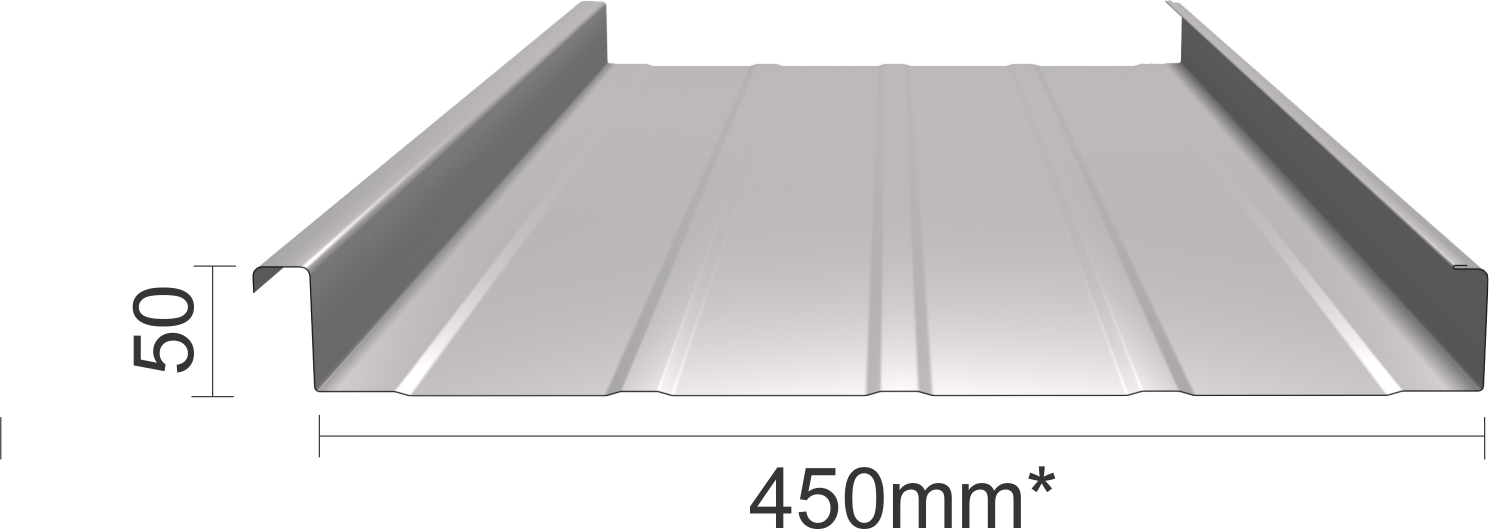

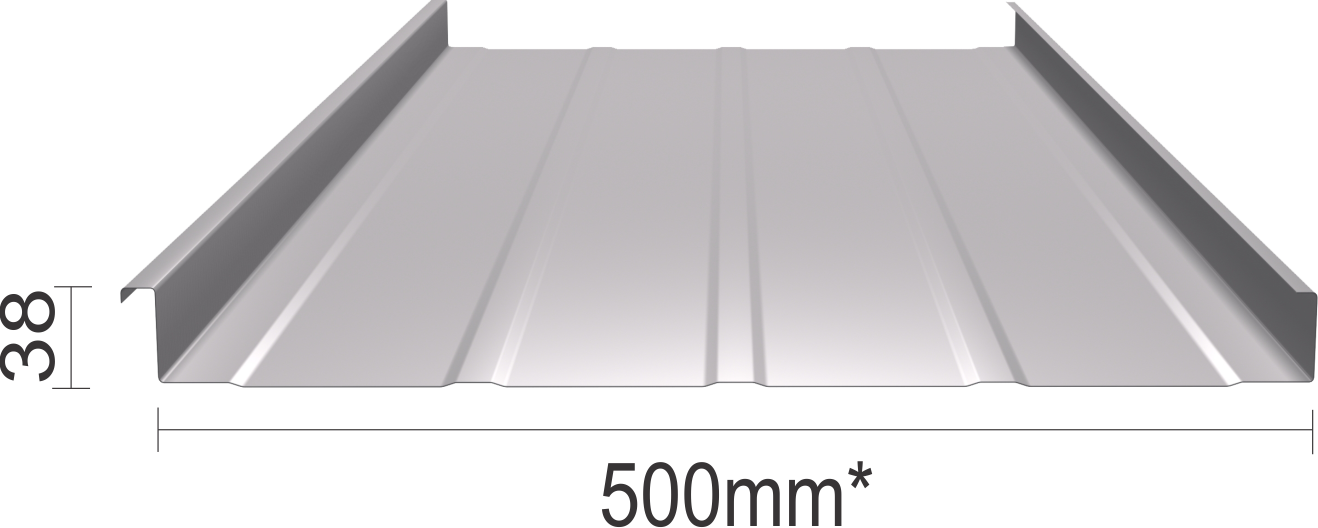

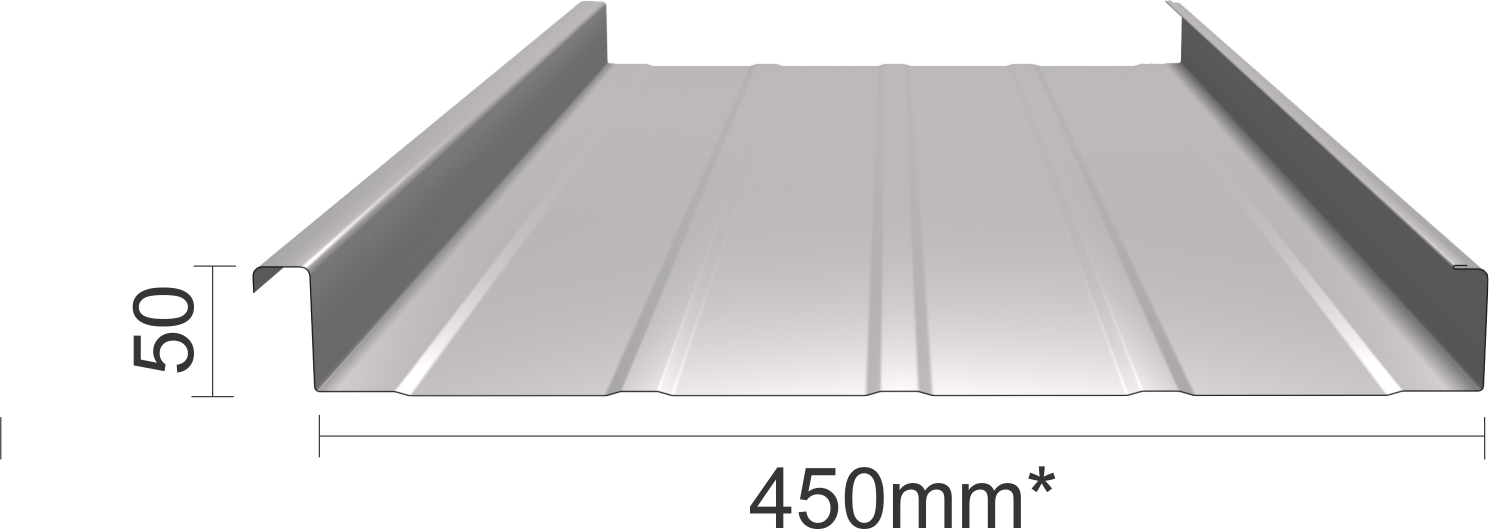

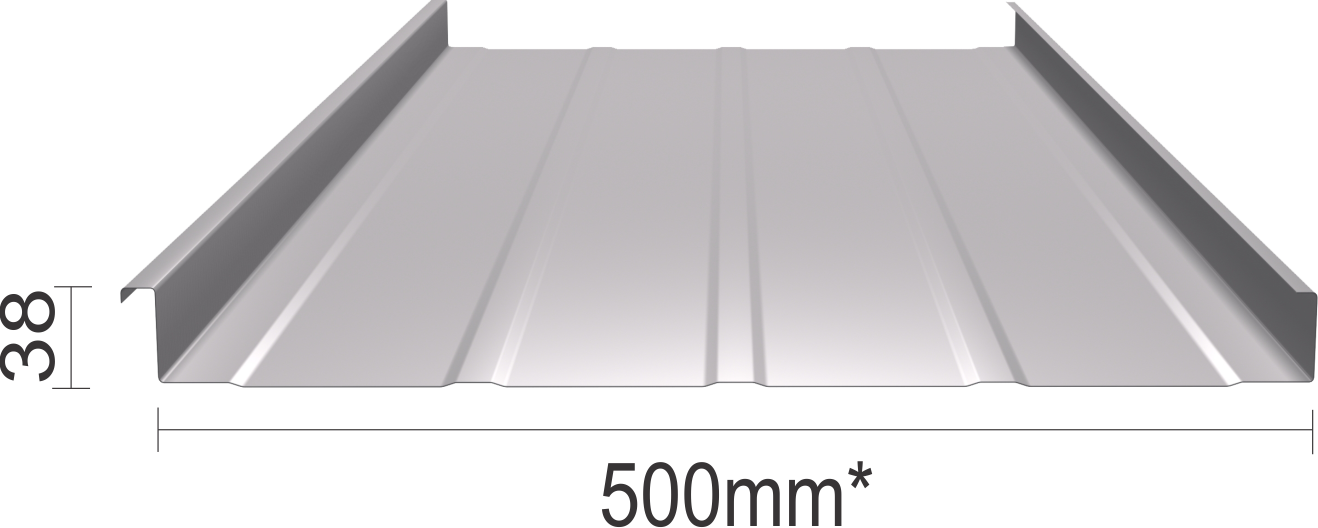

There are several standing seam sheets profiles, as conventional, which the geometry of the profile is changed by designers looking for new architectural purposes and in different resistances (Moment of Inertia). Currently we work with the following standing seam sheets profiles:

* The width of RW38 and RW50 sheets may vary according to the client needs, requiring the use of special coils widths. These profiles can be manufactured with useful width of 300 to 600mm.

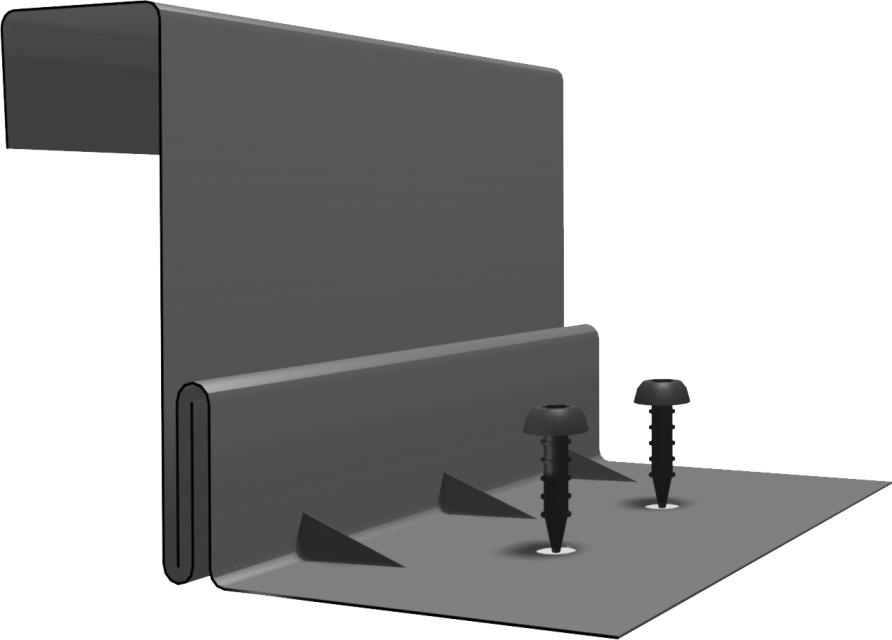

Clips

The fastening system is performed by special clips screwed on the roof support structure with the use of self-drilling fastener. These clips allow expansion or contraction of the sheets caused by temperature variations.

Mounting and Fixing the Sheets

The system can be suitable for any size, for small and large constructions, serving commercial, industrial and agricultural sheds, gyms, airports, supermarkets, pavilions, shopping, residential and others.

The sheets fixing process is called standing seam roof. It used an electric sealer which runs all ridge sheets, definitively fixing them to the clip and consequently to the support structure.

Obtaining excellent results in large areas, it can be also applied to existing roofs, waterproofing slabs and wall cladding system.

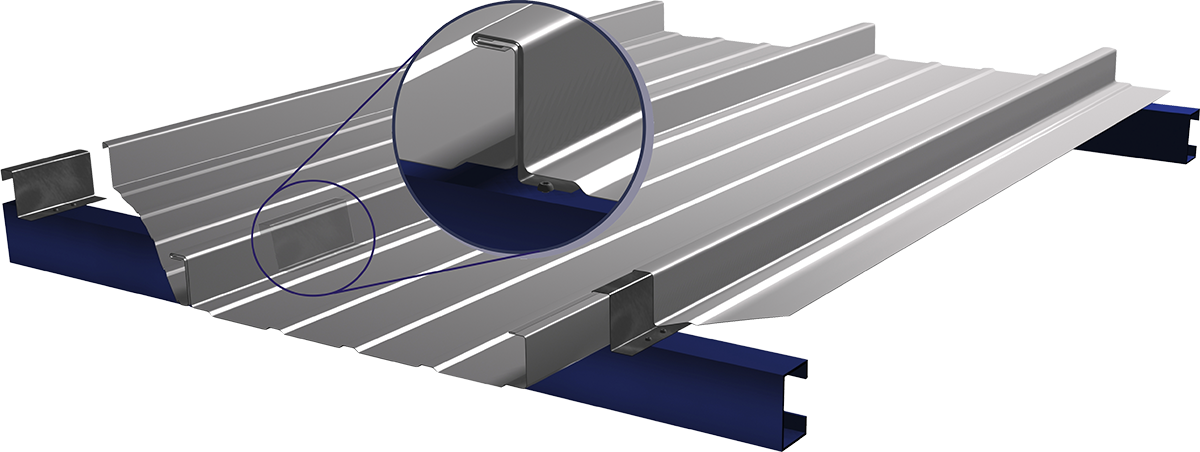

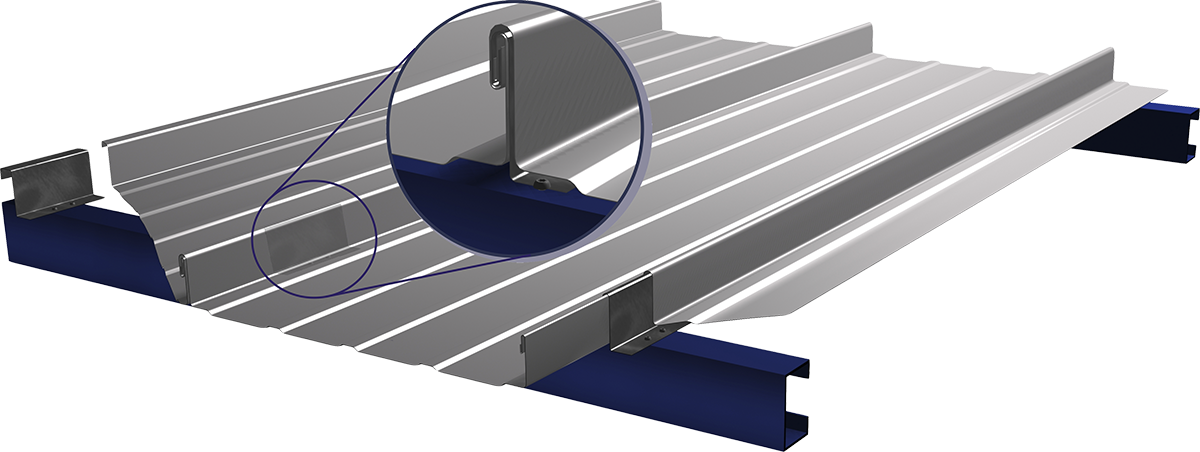

Standing Seam Roof

After fixing system installation, the sheets are continuously sealed by sealing or universal-zipper, by bending their crests of 90° to 180.

Joining a definitive and precise way sheet to the clip

Competitive Advantages

- Total tightness guarantee;

- Sheets seamless in overall length;

- Fixing without drilling on sheets;

- Production of sheet on site construction in any length;

- Small slopes for the roofs;

- Reduction or even elimination of internal stormwater networks;

- Faster completion of the construction;

- Very attractive architectural result;